Pneumatic rock drills are mainly used for two purposes:

1. The rock drill is a stone mining machine that uses the rotation and impact of the steel drill to drill holes in the rock, and is also used to demolish abandoned buildings.

2. It is mainly used to directly mine stone materials. The rock drill drills holes in the rock formations so that explosives can be put in to blast the rocks and complete the stone mining work or other stonework.

The applicable environment of rock drill:

1. It can work normally on flat ground or high mountains, in extremely hot areas above minus 40 degrees Celsius, or in extremely cold areas with minus 40 degrees Celsius. Pneumatic rock drills are used in mining, drilling, or construction, as well as cement roads or asphalt roads. Rock drills are widely used in construction, mining, fire construction, road construction, geological exploration, national defense engineering, quarrying or construction, and other fields.

rock drill bit material

The material of the rock drill bit is composed of two parts, one part is forged from 40Cr or 35CrMo steel, and the other part is made of tungsten-cobalt carbide.

What types of rock drills are there?

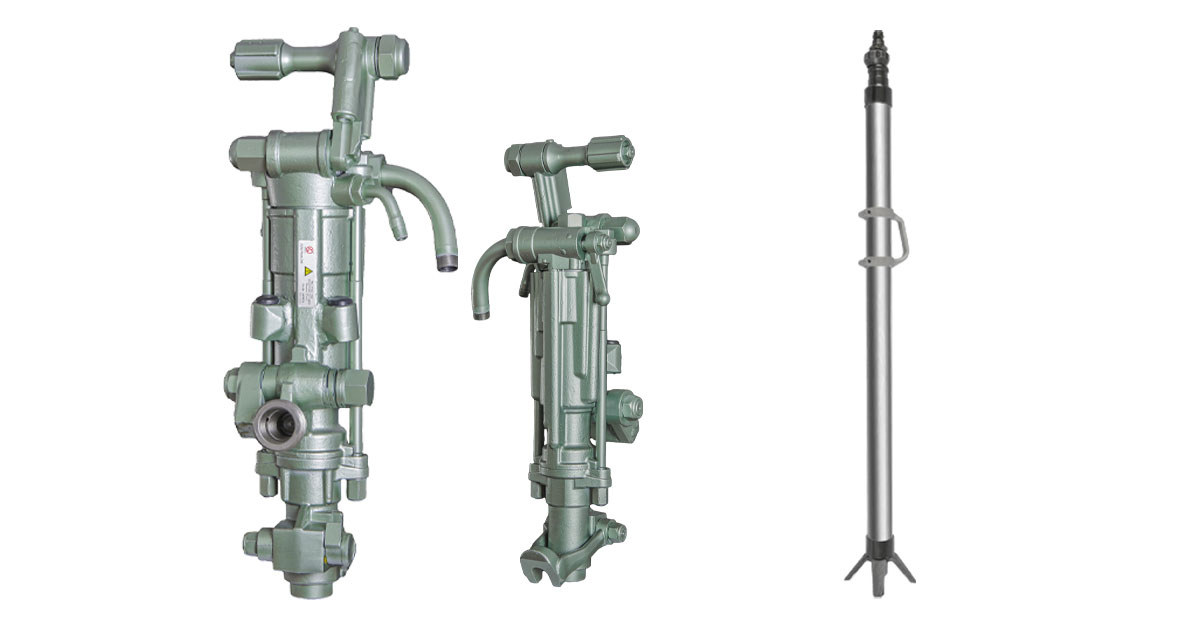

The company produces two types of rock drills, which are mainly used for direct mining of stone and mining, etc. The power source can be divided into pneumatic rock drills and internal combustion rock drills.

A detailed explanation of drive mode:

Pneumatic rock drills use compressed air to drive the piston to repeatedly strike forward in the cylinder so that the steel drills continue to gouge the rock. It is extremely convenient to operate, saves time, labor, fast drilling speed, and high efficiency. Pneumatic rock drills are the most widely used in mining.

The internal combustion rock drill only needs to move the handle as required and add gasoline to operate. Drill holes in the rock and the deepest hole can be up to six meters vertically downwards and horizontally upwards less than 45°. In high mountains or flat ground. It can work in the extremely hot area of 40° or the cold area of minus 40°. This machine has a wide range of adaptability.

push leg rock drill

The rock drill is installed on the air leg for operation. The air leg can play the role of supporting and propelling the rock drill, which effectively reduces the labor intensity of the operator so that the work of two people can be completed by one person, and the rock drilling efficiency is higher. Drilling depth of 2-5m, the diameter of 34-42mm horizontal or with a certain inclination of the blasthole, is widely used and favored by mining companies, such as YT27, YT29, YT28, S250, and other models are such as air-leg rock drills

Matters needing attention for rock drills and how to drill holes:

1. Determine the hole position and punching direction, the angle of the air leg erection, etc.

2. The drill pipe and the rock drill must be kept parallel

3. The working area of the rock drill and air leg (or propulsion device) should be stable.

4. If you change the position of drilling or gouging, change the angle of the air leg and replace the drill pipe, the speed should be faster.

5. Pay attention to whether the blast hole is round or suitable, check whether the drill rod rotates in the center of the blast hole, and always observe whether the discharged rock powder is normal and whether the rock drill is working normally.

6. Listen to the running sound of the rock drill, judge whether the shaft thrust, wind pressure, and lubrication system are normal, the sound of drilling holes, and judge whether joint faults are encountered.

7. Regular and timely adjustment of water volume, air volume, and air leg angle.

Reasons for abnormal rotation of the rock drill:

1. In case of insufficient oil, you need to refuel the rock drill

2. Whether the piston is damaged

3. Is there any dirt stuck on the air valve or other rotating parts, if necessary, please repair or disassemble and replace the necessary parts in time

Post time: Jun-08-2022